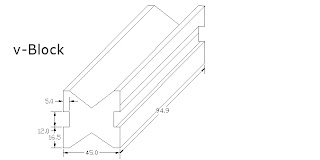

To prepare a v-Block

Procedure:

First of all clean and lubricate all the machine.

Moves cross slide towards the column face and stop it nearest position

Clamp the work piece between the vice jaws of appropriate height over strips

Remove arbor support from over arm & arbor with great care

Adjust milling cutter nearest the column face with the help of spacing collar

During the adjustment of milling cutter decides that friction of cutting teeth towards the fix jaw

Clamp arbor support nearest the cutter

Measure the diameter of cutter and calculate R.P.M by using this formula

R.P.M=C.S*1000/3.1416*D

Calculate the feed rate by using this formula

Feed rate=No of tooth*R.P.M* feed per tooth

Set work piece for up milling

To take depth of cut and starts machine & keep a paper between running cutter & work piece then move upward slowly the machine table.

To take possible depth of cut use the feed handle after this start coolant

After the use of coolant starts auto feed

Starts machining the 1st side and take it as reference

Then set the reference side with fixed jaw of vice & complete planning of 2nd side

Repeats this process until the required size is obtained

Then clamp work piece in vertical position as right angle accurately

Plain both ends of work piece obtain required length using depth of cut

Remove plain milling cutter &set 90 degree angular milling cutter on the arbor

Remove the work piece from the vice and layout it

Clamp the work piece in the vice according to the layout or operation

Level the job across the milling cutter & clear the job to take a depth of cut

Start v-slot by taking the depth of cut of 1mm in each turn

In case of v-slot in opposite side unclamped the work piece &then clamp to cut the v-slot in opposite side

Start v-slot by taking the depth of cut of 2mm in each turn &repeat it until required size

Clamp 10mm with side milling cutter after removing angular milling cutter

After clamping the work piece engraved center line

Start slotting by taking the cut of 1mm in each and repeat it upto required size

Cut the 2nd slot as previous operation

After completing the job clear all the burrs by filling

Clean up the machine and switch of all the machine control

1 comments:

Hi, I really appreciate you for all the valuable information that you are providing us through your blog.

manufacturer straight spline broaches

Post a Comment